Patented VSS™ Shim

How the shim helps to deal with noise in the braking system?

Shim is the best way to deal with noise in the braking system. Without shims, individual parts of the brake system can vibrate, thereby creating unpleasant noises.

Shims reduce the forces and the amplitude of vibration, this effect is achieved due to the damping material from which the shim is made. It increases the weight, which can quench oscillation between the caliper and the brake pad.

Also, the shim can act as a thermal barrier to provide the stable temperature of the brake pads for creation of a stable braking torque.

Patented Vulcanized Silencing System

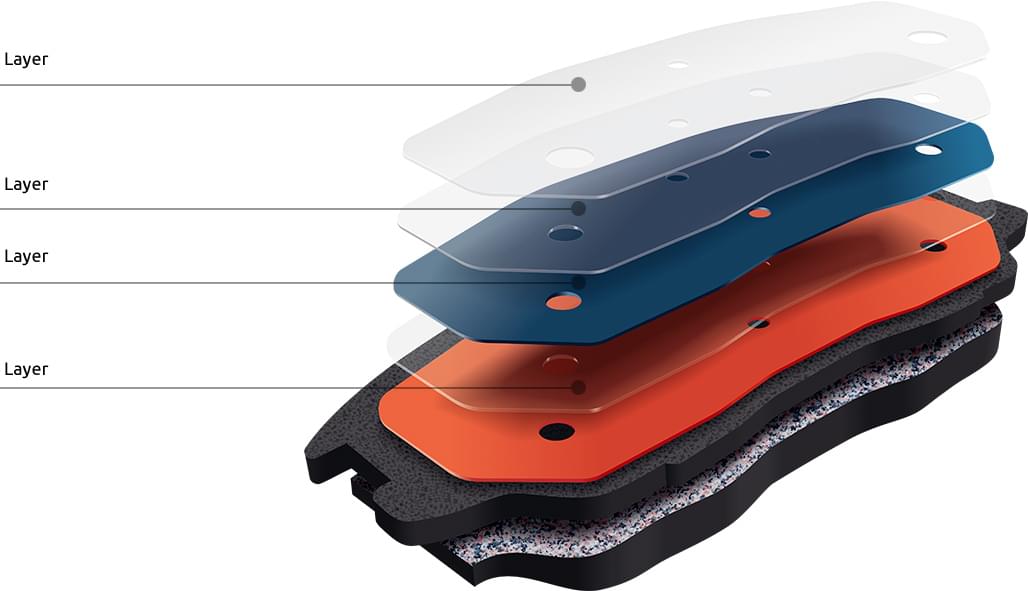

High-quality shim is made of several layers of material, each of which has different damping factors. Each of the layers is selected by engineers for a specific braking system individually to obtain the best NVH – Noise, Vibration, Harshness.

In Friction Master® brake pads different types of shims – from textured Constraint Layer (rubberized) to multi-layer and glass-plastic. The latest are used in the flagship lines Friction Master® Ultralife® and SPEED™.

A multi-layered shim using patented VSS ™ technology (Vulcanized Silencing System), where the rubber lining is vulcanized between metal layers, provide an unsurpassed level of vibrations and noises damping, thanks to the carefully selected damping factors of all components.